I have decided to answer a comment on a recent post here rather than in the comments section because (1) the answer to the question may help others that have the same problem and (2) because I think that the photos will help illustrate what I am trying to say.

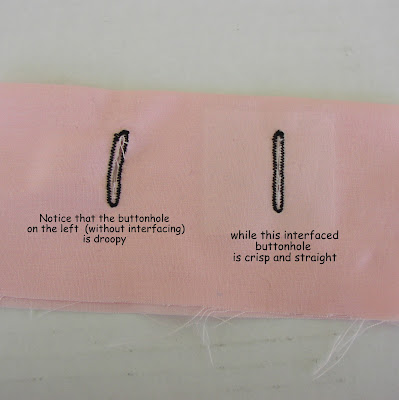

The question pertained to preventing "droopy buttonholes" (my words) that occur in knot jumpers. Any buttonhole causes a lot of stress on a garment's fabric around it just by the normal movement of the body. So my rule of thumb in my own sewing projects is that I NEVER, EVER make a buttonhole until I first interface the fabric. In the case of this jumper and this jumper, I reinforced the entire yoke, because the entire yoke can begin to "droop" with the stress of the weight of the full skirts that they must support.

There are other times that in an infant dress or doll's dress I may choose only to "spot interface a buttonhole" to prevent bulk while still reinforcing it. In such a case, I would cut two squares of light to midweight interfacing. Each square would be slightly larger than the length of the buttonhole. Then, I fuse them to the inside of the fabric where the buttonhole will be located. (In the illustration below, I used heavyweight interfacing so that it woud be more visible in the pic.)

The advantage to interfacing both insides in that it will also help prevent fraying of the fabric in the same way a "fray check" product would.

The advantage to interfacing both insides in that it will also help prevent fraying of the fabric in the same way a "fray check" product would.

In preparing the example of buttonholes above, I was also struck by the appearance of the buttonhole even before use. Notice that the fabric fibers on the right buttonhole were stabilized, and therefore did not shift or stetch as the buttonhole was being sewn.

Another thing that can be seen from the above photo, is that the stess of cutting the buttonhole also was minimized in the interfaced buttonhole. One more little note about interfacing is illustrated in the photo above, and that is the importance of using the proper weight of interfacing for your projects. When the weight of the interfacing matches your fabric weight you will not see the interfacing "shadow" that is evident in the photo above. If you see "where the interfacing has been used", you need to be using a lighter weight interfacing.

I'm running a little short on time here, so I'm going to address how I keep the knots from slipping through the buttonholes in another post.

Hope this helps.

2 comments:

Hmmm. I DID interface the buttonholes. I can't remember if I did both sides or just one though and I only did the "spot" interfacing so that may have made a difference too. Or maybe not a heavy ENOUGH interfacing?! Hmmm.

Very insightful post. I now know whatever happened was MY fault, because it IS possible to use buttonholes in this instance. Which means, try try again! :-)

Rebecca,

With a medium-weight cotton, you shouldn't have had to use anything more than a medim-weight interfacing. Interfacing both sides does give a little extra support without the "shadow". You could interface the outer yoke completely and then only spot interface the inner yoke.

Anyway, I only gave you the first part of the solution in this post. I addressed the second part here. Hope this helps you out.

Post a Comment